Introduction

Gear motors—simple yet powerful devices that combine a motor and a gear train—are the backbone of modern packaging lines. They transform electric energy into precise mechanical motion, enabling high-speed cutting, folding, labeling, and palletizing operations. In this article, we’ll walk through real-world experiences from our engineering labs and factory floors, illustrating how selecting the right gear motor can boost throughput, reduce energy consumption, and lower operating costs.

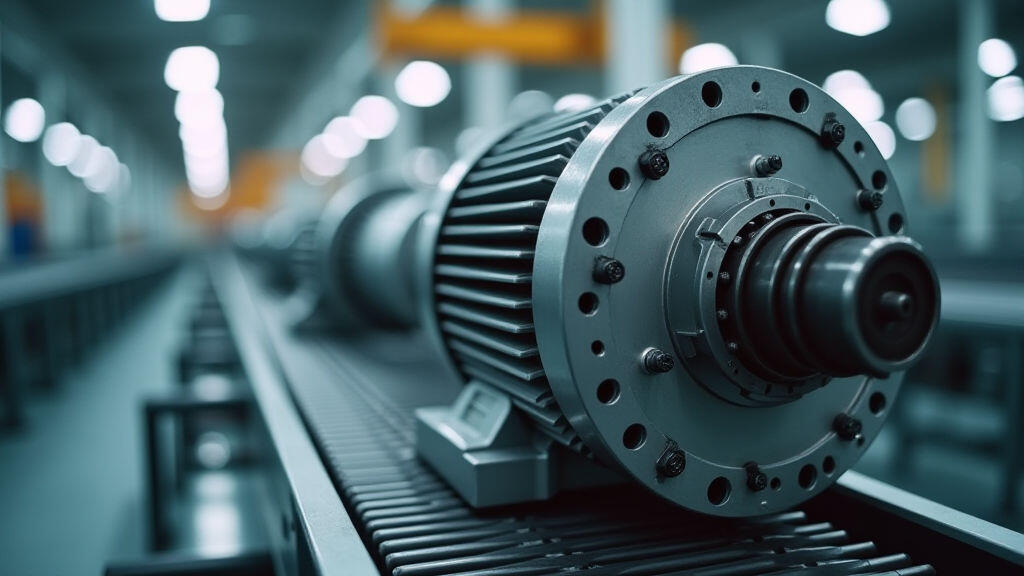

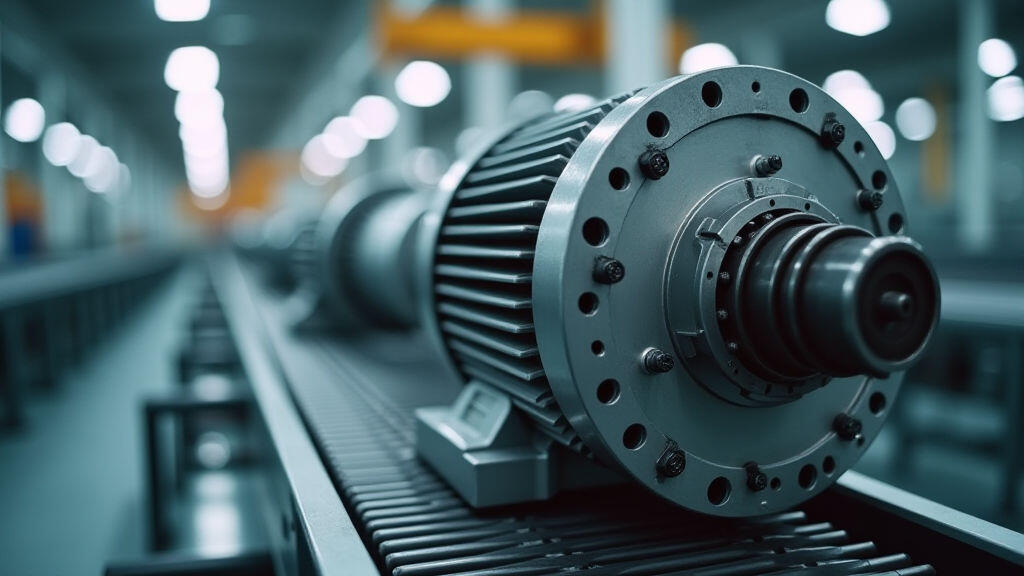

1. What Is a Gear Motor?

At its core, a gear motor consists of a small electric motor whose shaft is coupled directly to a gear set. The gears translate the motor’s rapid rotation into slower, higher-torque motion suitable for driving mechanical systems. Two main classifications exist:

Key specifications that matter to packaging engineers include: torque output, rotational speed (RPM), efficiency, cycle life, and ambient temperature tolerance.

2. Why Gear Motors Matter in Packaging Equipment

Packaging operations demand repetitive, precise movements. A gear motor’s high torque and low RPM enable:

Moreover, integrating gear motors with variable frequency drives (VFDs) allows real-time speed adjustments, reducing energy consumption by matching motor output to production needs.

3. Selecting the Right Gear Motor

Choosing a gear motor is more than picking a size that fits. Consider the following checklist:

| Factor | Practical Consideration | |--------|------------------------| | Power Rating | Match to the load’s peak torque; oversizing saves future upgrades. | | Speed Requirement | Must cover the full range of packaging speeds; high-speed lines often need motors that can run up to 3000 RPM. | | Duty Cycle | Continuous applications need motors rated for 100% duty cycle; intermittent tasks can use 30–50% ratings. | | Environment | Exposure to dust or chemicals mandates encapsulated models. | | Maintenance Access | Rounded housings and quick-release shafts simplify servicing. |

An iterative approach—testing motors under actual load and monitoring temperature rise via thermocouples—helps fine-tune selection.

4. Case Study 1: High-Speed Carton Folder

In 2024, a mid-sized packaging firm needed to replace an old folding machine to increase output from 200 to 400 cartons per minute. The key challenge was to achieve higher cadence without compromising fold quality.

Solution: We installed a 150 W direct-drive gear motor with a 1:10 gear ratio.

Implementation: The motor’s shaft was coupled to a Fuji fitting on the folding blade. A VFD allowed the operator to set a peak speed of 250 RPM, translating to a 10 rpm blade movement.

Outcome: The machine achieved the target throughput, reduced cycle time by 60 %, and the torque ensured consistent fold angles. Energy consumption dropped by 20 % thanks to VFD control.

5. Case Study 2: Automated Labeling System

A packaging plant required 100% automation of its labeling station to cut costs. The system had to handle multiple label types and rapidly switch between them.

6. Performance Metrics and Troubleshooting

When gear motors are part of a packaging line, keep an eye on:

Regular maintenance—lubricating gear teeth, inspecting shaft bearings, and tightening couplings—prevents costly downtime.

7. Future Trends: AI, Smart Sensors, and Beyond

Next-generation packaging lines leverage machine learning to predict motor failures before they happen. By embedding vibration sensors and ECM-driven diagnostics, an AI model can flag abnormal patterns, prompting proactive maintenance.

Smart gear motors are now available with built-in diagnostics, reporting torque curves and temperature via MQTT to a central cloud dashboard. These “connected” motors fit seamlessly into Industry 4.0 ecosystems, aligning with the trending Global Packaging Automation Summit 2025 where companies showcase predictive maintenance strategies.

Conclusion

Gear motors, though often overlooked, are pivotal in transforming electric power into the precise, high-torque motion required by packaging systems. From high-speed carton folding to automated labeling, the right gear motor choice can unlock significant production gains, energy savings, and higher product quality. As the packaging industry embraces digitalization, integrating smart, sensor-equipped gear motors will become standard, enabling predictive maintenance and real-time optimization. Embracing these technologies today positions firms to stay ahead in a demanding market—highlighting gear motors not just as drivers of mechanical motion but as catalysts for innovative, efficient packaging solutions.

Leave A Reply

Your email address will not be published. Required fiels are marked